- #Single phase motor winding resistance chart how to

- #Single phase motor winding resistance chart cracked

The starting winding must be disconnected since it would increase the losses in the motor. The motor then operates solely on the running winding.

#Single phase motor winding resistance chart cracked

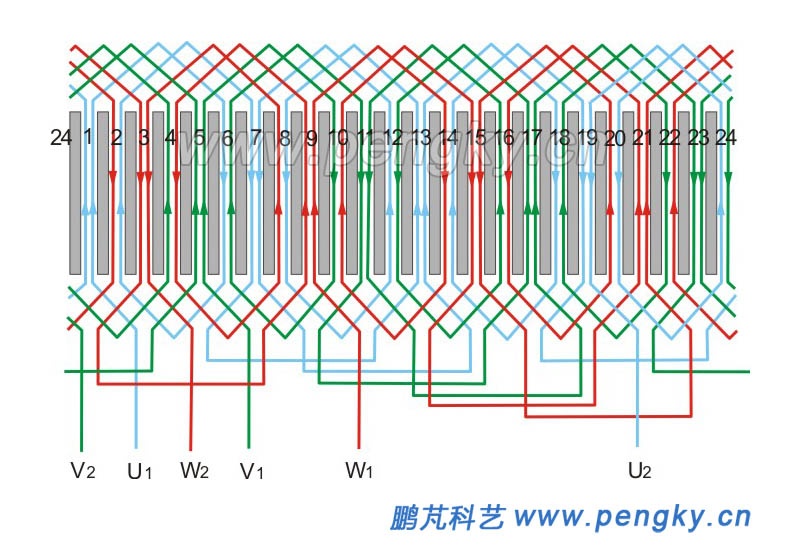

Once the motor reaches near design operating speed, the centrifugal switch activates, opening the contacts and disconnecting the startup winding from the power source. The single-phase rotor test is used to search for cracked rotor bars and is performed with the motor still together, but disconnected from power. The phase of the magnetic field in this startup winding is shifted from the phase of the mains power, allowing the creation of a moving magnetic field which starts the motor. The starting direction of rotation may be reversed simply by exchanging the connections of the startup winding relative to the running winding. The lower L/ Rratio creates a small phase shift, not more than about 30 degrees, between the flux due to the main winding and the flux of the starting winding. The starting winding is wound with fewer turns of smaller wire than the main winding, so it has a lower inductance ( L) and higher resistance ( R).

#Single phase motor winding resistance chart how to

Learn More: What is Crawling of Induction Motor & How to Avoid it? When the motor is starting, the startup winding is connected to the power source via a set of spring-loaded contacts pressed upon by the stationary centrifugal switch. This creates an LR circuit which slightly shifts the phase of the current in the startup winding. In the split-phase motor, the startup winding is designed with a higher resistance than the running winding. or motor defective Condition causes improper resistance readings. Cable insulation, splice See E pages 48, 49. Defective pressure Inspect switch and/or switch or control - replace if control device necessary. Power supply: 230V single-phase unless otherwise specified by. starter, cable or improper resistance motor readings. This simple (no capacitor) arrangement serves well for motors up to 1/3 horsepower (250 watts) driving easily started loads. This resistor heats the machines when stopped and thus prevents condensation inside the machines.

This coil produces a moderate starting torque, which is disconnected by a centrifugal switch at 3/4 of synchronous speed.

About 30 o of phase difference may be obtained. (Figure below) With lower inductance and higher resistance, the current will experience less phase shift than the main winding. If an auxiliary winding of much fewer turns of smaller wire is placed at 90 oelectrical to the main winding, it can start a single phase induction motor. Resistance split-phase motor induction motor

0 kommentar(er)

0 kommentar(er)